Last Updated on 2025-06-24 by Car Parts Expert

The BPGA module is one of the core components of Peugeot’s engine management system, especially in 1.6T models such as 3008. However, due to its design defects or failures caused by long-term use, BPGA module problems have become a problem for many car owners. This article will explore the working principle, common fault manifestations, detection methods and replacement steps of the BPGA module in depth to help car owners better understand and solve related problems.

How does the BPGA module work?

The full name of the BPGA module is “Bosch Motronic ME7.4.4 system, Plastic Gasoline Air-cooled”, which is part of the Peugeot engine management system. It controls key parameters such as fuel injection amount, ignition timing and intake volume by collecting and analyzing various sensor data of the engine to ensure the balance of engine performance, economy and environmental protection.

The BPGA module is usually installed inside the engine control unit (ECU) and is responsible for managing the power supply and charging system. It ensures the stable operation of the vehicle’s power system by monitoring data such as battery voltage and generator output. When the module detects an abnormality, it will protect the vehicle system by reporting an error on the dashboard or restricting engine start.

What are the common fault manifestations of BPGA modules?

The fault manifestations of BPGA modules are diverse, mainly including the following:

Battery charging or power supply system failure: This is the most common fault manifestation, and the dashboard will display relevant warning information.

The engine cannot start: In a low temperature environment, the module may have intermittent failures, causing the vehicle to fail to start.

Electronic handbrake and brake system failure: After replacing the module, errors such as “parking brake failure” or “brake system failure” may appear.

Warning lights are always on: Even after replacing the module, some warning lights may still light up, affecting the driving experience.

- Sale!

Rated 5.00 out of 5 based on 1 customer rating

Rated 5.00 out of 5 based on 1 customer rating$499.00Original price was: $499.00.$389.00Current price is: $389.00. - Sale!

Rated 5.00 out of 5 based on 1 customer rating

Rated 5.00 out of 5 based on 1 customer rating$399.00Original price was: $399.00.$289.00Current price is: $289.00. - Sale!

Rated 0 out of 5

Rated 0 out of 5$99.90Original price was: $99.90.$89.90Current price is: $89.90. - Sale!

Rated 0 out of 5

Rated 0 out of 5$99.90Original price was: $99.90.$89.90Current price is: $89.90.

What is the fault detection method for BPGA modules?

Dashboard error: When the dashboard displays “battery charging or power supply system failure”, the BPGA module problem should be suspected first.

Voltage detection: Use a multimeter to detect the battery voltage and generator output to eliminate the possibility of battery or generator failure.

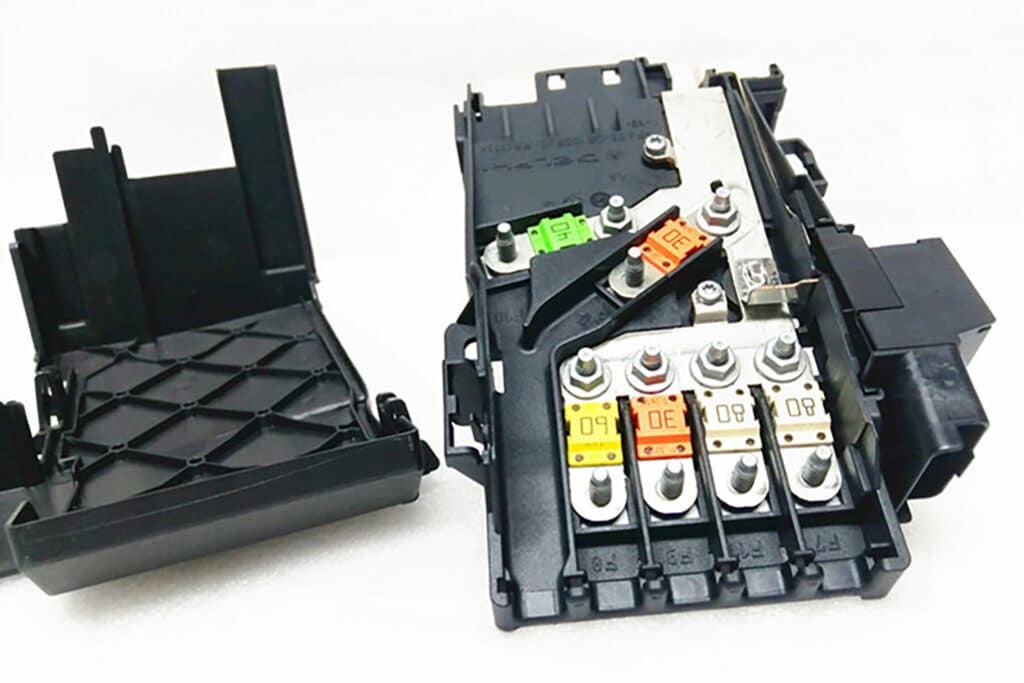

Module appearance inspection: After removing the BPGA module, check whether its appearance has physical damage such as ablation and cracks.

Compare the old and new modules: If the fault persists after replacing the module, you can compare the resistance, jumper and other details of the new and old modules to find out the differences.

How to replace the BPGA module

Preparation

Buy the right module: Make sure the new module matches the vehicle model and check if there are any jumper or resistance differences.

Tool preparation: Prepare tools such as screwdrivers, wrenches, and multimeters.

Replacement steps

Remove the old module:

For 1.6T models, the BPGA module can usually be removed without removing the air filter.

Disconnect the power supply and carefully unplug the module’s connection wires.

Install the new module:

Install the new module in place and make sure the connection wires are plugged in tightly.

If the new module lacks a jumper, you can remove it from the old module and install it on the new module.

Testing and debugging:

Start the vehicle and observe whether the dashboard still reports an error.

If “parking brake fault” or “brake system fault” appears, you can try to replace the resistor on the module.

Notes

Module compatibility: Make sure the new module matches the vehicle model completely to avoid faults due to different specifications.

Jumper and resistor check: The jumper and resistor specifications of the new and old modules may be different, so they need to be carefully compared and adjusted.

Troubleshooting: If the fault persists after replacement, further inspection of the circuit or other related components may be required.

Temporary solution for BPGA module failure

If the module cannot be replaced immediately, the following temporary solutions can be tried:

Tap the module: Tapping the BPGA module with a fist can sometimes temporarily restore its function.

Power off and restart: Disconnecting the negative terminal of the battery and reconnecting it after waiting for a few minutes may clear the temporary fault.

Shielding the module: Although not recommended, the problem can be temporarily solved by shielding the module, but it may cause other electronic system failures.

BPGA is a key component of Peugeot's engine management system

As a key component of Peugeot’s engine management system, the failure of the BPGA module will directly affect the normal operation of the vehicle. By understanding its working principle, fault manifestations and replacement methods, car owners can better deal with related problems. Although replacing the module is the ultimate solution, temporary measures can also provide some help in emergency situations.