Last Updated on 2025-06-23 by Car Parts Expert

The use of liquid urea fuel injector nozzle valves in diesel engines has become a common practice in recent years due to their ability to reduce harmful emissions and improve engine efficiency. These innovative components play a vital role in the selective catalytic reduction (SCR) process, which helps to minimize the release of nitrogen oxides (NOx) into the atmosphere. In this article, we will explore the functioning of liquid urea fuel injector nozzle valves, their benefits, and their impact on the automotive industry.

Functioning of Liquid Urea Fuel Injector Nozzle Valves

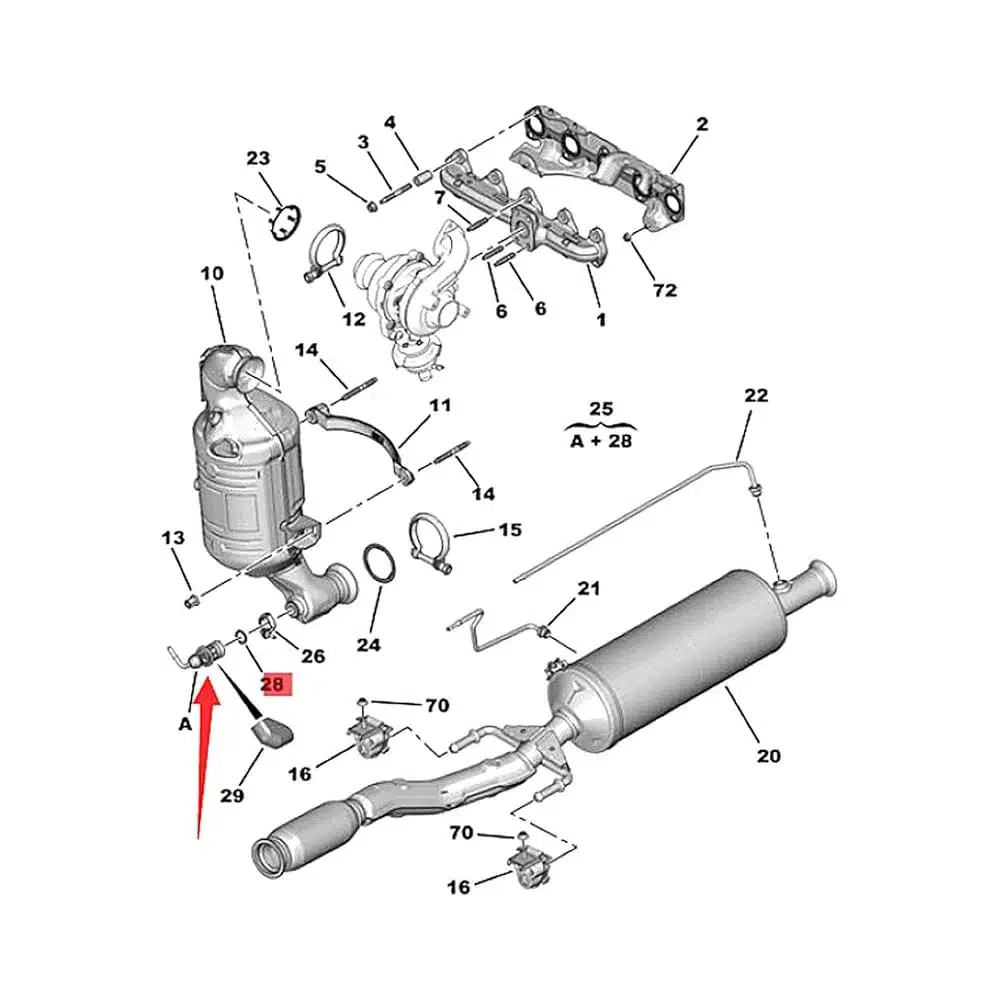

Liquid urea fuel injector nozzle valves are designed to inject a precisely metered amount of urea solution into the exhaust stream of a diesel engine. This urea solution, known as diesel exhaust fluid (DEF), is typically composed of 32.5% high-purity urea and 67.5% deionized water. When injected into the hot exhaust gases, DEF vaporizes and decomposes into ammonia (NH3) and carbon dioxide (CO2).

The ammonia generated from DEF reacts with the NOx present in the exhaust stream in the presence of a catalyst, such as a vanadium or titanium-based material. This chemical reaction converts the harmful NOx compounds into harmless nitrogen (N2) and water vapor (H2O). By facilitating this process, liquid urea fuel injector nozzle valves help diesel engines meet stringent emission standards and reduce their environmental impact.

Benefits of Liquid Urea Fuel Injector Nozzle Valves

- Emission Reduction: Liquid urea fuel injector nozzle valves contribute significantly to the reduction of NOx emissions, a major contributor to air pollution and smog formation. By converting NOx into harmless nitrogen and water, these components help to improve air quality and comply with emissions regulations.

- Improved Fuel Efficiency: The SCR process enabled by liquid urea fuel injector nozzle valves allows for the optimization of the engine’s combustion process. By reducing the concentration of NOx in the exhaust gases, diesel engines can operate more efficiently, leading to improved fuel economy and lower operating costs.

- Extended Engine Life: By minimizing the formation of harmful pollutants, liquid urea fuel injector nozzle valves help to protect critical engine components from corrosion and wear. This can lead to a longer service life for the engine and lower maintenance requirements.

Impact on the Automotive Industry

The introduction of liquid urea fuel injector nozzle valves has had a transformative impact on the automotive industry, particularly in the realm of diesel engine technology. With stricter emissions standards being imposed worldwide, manufacturers are increasingly turning to SCR technology to meet these requirements while maintaining the performance and efficiency of their vehicles.

The widespread adoption of liquid urea fuel injector nozzle valves has also spurred advancements in catalyst development and exhaust aftertreatment systems. These innovations have not only enabled diesel engines to achieve lower emissions levels but have also paved the way for the development of cleaner and more sustainable transportation solutions.

Liquid urea fuel injector nozzle valves represent a crucial component in the quest for cleaner and more efficient diesel engines. By enabling the SCR process and reducing NOx emissions, these valves play a key role in enhancing environmental sustainability and mitigating the impact of transportation on air quality. As technology continues to evolve, liquid urea fuel injector nozzle valves will undoubtedly remain a cornerstone of modern emission control systems, driving further improvements in engine efficiency and emissions reduction.

Any question pls contact Shany Whatsapp +86 18902611680